Have you just developed a prototype for a new part of your machinery? If so, great! You have gone through the first crucial process of machinery, product, or equipment development! You hired a designer, got the drafts, and then created a product in line with the drawing or model. You may think you are ready to go to the next level of creating the final product. However, there is another part of the process you may not have thought about.

You want to ensure the prototype that you have created matches up with the 3D CAD (computer-aided design) model that was created by the designer. So, how do you do this? Also, do you even have the time to do this? Probably not, and that is where we can come in.

Cad Crowd works with CAD inspection professionals who can come in and make life easier for you and your team. They can travel to your worksite and use 3D scanning technology to see if there are deviations between the physical prototype and the CAD model.

Even if the greatest of care is taken with developing your CAD designs, a lot can happen between the design process and prototyping or manufacturing. There might have been an error regarding a calculation, or incorrect materials may have been used for the prototype. Whatever the situation is, Cad Crowd's part-to-CAD inspection services will ensure our inspectors aid in finding any potential mistakes or deviations from your initial 3D CAD model.

Cad Crowd believes not only in the importance of helping companies accomplish their design goals, but e also feel it is essential to provide insightful education into design processes that can help you make the best decision for your company.

So, now that you know that you have an extra step in the design process and have some support in accomplishing this, we want to provide some crucial and helpful education. The next section will take you a little deeper into what CAD inspection is. We will also further address why this service is necessary for your company. So, we invite you to read on for more information below.

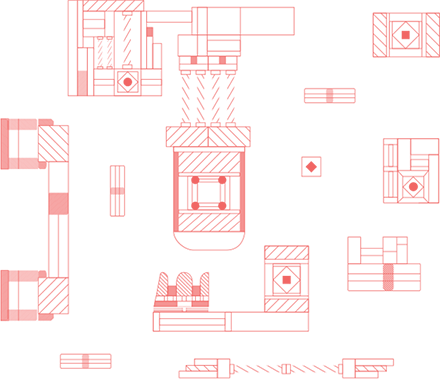

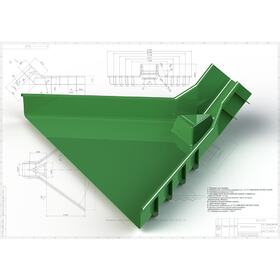

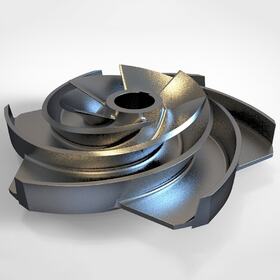

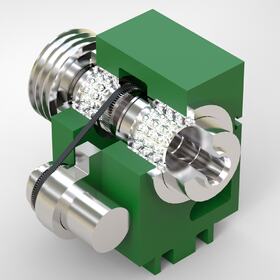

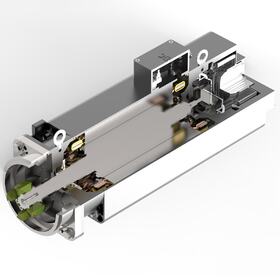

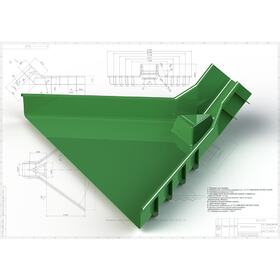

So, we have delved into why part-to-CAD inspection services should be the next step in your manufacturing or prototyping process, but we still have to discuss the definition of this procedure. At its core, part-to-CAD inspection services are when an inspector checks a physical prototype to see if it matches the specifications set for it in the 3D model. They will scan the part with a piece of 3D scanning technology equipment that allows them to measure the physical item against the 3D model. From there, they can tell if there are any deviations from the original model.

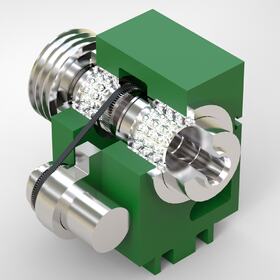

The sizing might be off by an inch, or there could be small physical errors that are not visible with the naked eye. Either way, this process is meant to find these mistakes, so you do not mass produce an item that is not in alignment with your original specifications. One small mistake can halt production, costing you significant time and money. So, part-to-CAD inspection services are a necessary component of your prototyping and design processes.

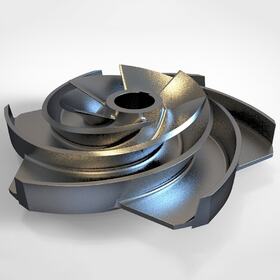

It also has a wide range of industry applications. Everything from machinery to manufacturing and architecture can benefit from the use of part-to-CAD inspection services.

We know how crucial it is for you to have accurate prototypes and models before going through the process of mass-manufacturing. This reason is why we have developed a global network of pre-vetted and handpicked freelancers who can assist you during this process. We can send groups of freelancers to your design site to work with you and support your quality control team.

Many of our inspection freelancers have experience working with teams large and small, while also handling projects of various complexity. Their ultimate goal is to ensure you can produce designs that adhere to the specifications of your team and clients. The last thing you want is to have to start all over again with a faulty product or piece of machinery. So, we invite you to use Cad Crowd's part-to-CAD inspection services to receive help you need.

In addition to ensuring accuracy, part-to-CAD inspection services come with many benefits to your company. See why this process is essential and how else it can bring advantages to your business:

Decrease the time of manufacturing and prototype cycles – Nothing slows down a project more than mistakes and miscommunication. The goal of part-to-CAD inspections is to find errors and deviations from specifications before a prototype goes on to final production. If you miss these mistakes, then the manufacturing process—along with the cost—will rise exponentially. You can bypass these unfortunate situations by investing in part-to-CAD inspections.

Get a second eye on products – Yourself and your team have spent weeks and maybe even months on product and manufacturing projects. As a result, because you are so close to the process, it can be challenging to see mistakes or situations that can bring on potential errors. So, you can benefit from having a different set of eyes take a look at these items. They are bringing an entirely new and unique perspective and can more easily see issues or errors for that reason.

Improve the quality of your products – As a business owner, your main goal is to make your customers satisfied with the product or service they are receiving from you. One of the main ways to do that is to ensure you are producing high-quality products. Part-to-CAD inspection services allow you to stick to the original plan for a product by ensuring it meets the initial specifications. The chances are high that your specifications were created with the needs of your customers in mind. So, part-to-CAD inspections allows you to adhere to these standards.

See accurate results – Many times, mistakes will not be visible to the naked eye, and even if they are, there is no way of knowing how far they are deviating from your specifications. Today, inspectors can use 3D scanning tools to not only detect deviations, but they can also more accurately produce results through mediums like color mapping and data visualization to inform you of where the variances are occurring. You have a lot on your plate, and you don't need ambiguous or complex data regarding where mistakes are. Fortunately, today's technology takes the guesswork out of this process.

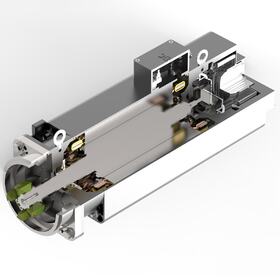

It's cost-effective – The days of having to take your part to another facility for testing, or buying expensive equipment to do it at your facility are over. Our inspectors can bring portable 3D scanning technologies to your worksite and conduct the scans without you having to leave the area. This step takes away the expense of transporting prototypes, buying your own scanning equipment, or dealing with the mistakes you wouldn't have caught without this technology. Also, instead of paying for equipment or hiring a salaried employee to handle this process, you can only pay for the time you need from a freelancer. All the way around, you and your team stand to benefit from this process financially.

Receive results quickly – Since the part-to-CAD inspection process is digital, you can feel confident that you will receive results fast. This reason is another way the prototyping and manufacturing process is considerably shortened. This 3D scanning technology is rapidly collecting data and producing results. So, you can expect to wait to receive information about any specification deviations to be much smaller.

Part-to-CAD inspection services are meant to ease the workload on your staff. The time, attention, and resources that are needed to produce high-quality products that fit your specifications are hard enough. Adding the measurement of deviations and preparing to fix them is a tall order.

This reason is why Cad Crowd specializes in getting entrepreneurs, small businesses, and even large corporations the design help and support they need. So, in addition to connecting businesses with designers, we can also provide teams of inspectors that allows you to take advantage of the benefits mentioned in this section.

We understand that you have a business to run. From managing employees to making customers happy, your goal is to operate your business successfully. This step is where we come in. We know that you have a lot on your plate, and we want to help make it easier to accomplish your core business activities while ensuring your customers are receiving high-quality products. This is why we are committed to connecting experienced and exceptional design freelancers with entrepreneurs and their companies through our part-to-CAD inspection services.

Whether you need help inspecting a new piece of equipment, an engine, a robotic machine, or a portion of a new building, Cad Crowd's part-to-CAD inspection services provide a global network of inspectors and designers who are available to help.

All designers are pre-vetted, handpicked by engineers, and bring a wide range of valuable experience to clients. There are a variety of ways we can connect you to our talented freelancers, and we invite you to select the way that works best for you and your company.

We hope to be the team that helps you with your next part-to-CAD inspection project. If you are interested, we invite you to request a free quote today.

At Cad Crowd, we have a network of the best CAD services on the market. Find out how it works.