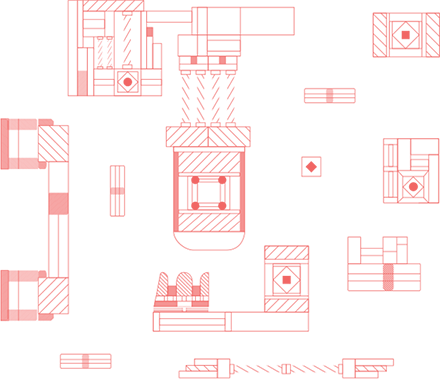

There are several stages of new product design. Enormous amounts of time and energy go into the ideation of new commercial or industrial objects. Technical engineers draw up blueprints and other 2D illustrations of an item’s schematics. To see more of a product’s purpose and intended design elements, animators may render a 3D model. In order to see the full functionality of a product, however, companies often require a prototype design as well.

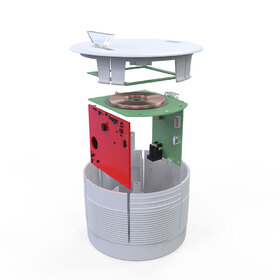

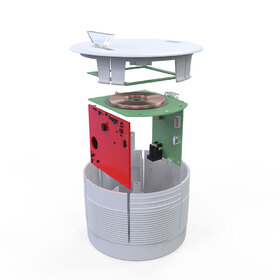

In many ways, a prototype compares favorably to a 3D model or product animation. Prototypes essentially manifest the physical properties of the product. This occurs at the end of the initial round of ideation, design, and engineering phases. When manufacturers want to know exactly how the product will look and feel, they develop a prototype.

A prototype design engineer is a necessity in order to build a working model of a company’s product. Consider mechanical engineering design. Aeronautics. Mining. Automotive parts and engineering. All of these, and many more besides, require prototypes. To ascertain the working features of their goods and materials, nothing beats a well-made prototype. In order to build it, however, one must have a prototype design engineer to create the model from which it will be constructed.

Moving past the prototyping phase could appear to shave off a little time in the design and manufacturing process. However, all this does is cause future headaches in the development stages and unnecessary expense. Think of it this way. You typically try on shoes before you purchase them. You certainly take a new car for a spin before committing to a lease. Why would you want to forego this process with your costly and labor-intensive designs? Consider how much time and money you could save during development. The truth is, you likely will not be able to know the full scope of your product until you interact with it. After all, the same will be true of your clients and customers.

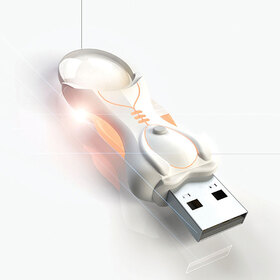

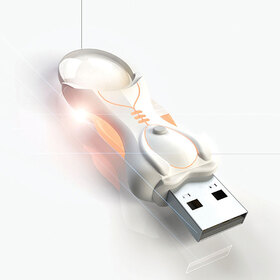

Prototype design engineers make use of the newest engineering and design software in order to build 3D models. These renderings are based on precise mathematical calculations to bring a design to life in three dimensions. You can think of this particular kind of 3D model as a virtual version of a prototype, before it is cast in plastic, metal, or other materials. The engineers perform a variety of virtual functional testing on the prototype via the rendering engines. This enables them to make sure that the design is of the highest quality and meets the most rigorous industry standards.

From here, the design engineers modify their models, which are sometimes referred to as “parametric.” This just means within specified parameters. There are many kinds of parameters: proof-of-principle, form study, user experience, visual, and functional. Based on what schematics they are given or develop from the manufacturing firm, they build out whatever is necessary to construct the item itself. This is all done before the actual manufacturing development of the product.

A virtual prototype, that only exists on a computer screen, will test a product to the limits of its capability, but the next natural step is to produce a physical prototype. This will enable full testing of the product’s functionality. That said, the fewer you build, the less you will ultimately end up spending. This is why the best prototype design engineers are necessary. They create the highest quality virtual model so that your physical prototype can be a one-and-done situation.

Many engineers at the highest level in mechanical design have years of experience and graduate degrees. They work with you from a basic idea all the way to the virtual prototype that allows you to envision your product as clearly as the real thing. From this model, you can discover any hidden defects in the product’s design or engineering, build out the existing design, and even easily expand into complementary products.

Knowing the facets of a prototype design helps you understand its many features and values. However, so many of these facets are technical in nature and can be tricky to translate into tangible benefits for a particular company and its client or customer base. In other words, what is the Return on Investment (ROI)? ROI can be notoriously difficult to determine with certainty. That said, there are few things as clear as cost savings, which come rolling in with a well-designed and -engineered prototype.

Digging into the specifics, though, one is able to swiftly take stock of the boon of prototype design. For one, it becomes infinitely easier to communicate the vision of your product with collaborators. Discussing the parameters of your product with manufacturers requires documentation and blueprints, of course. Consider what those same conversations would look like with a prototype design in hand. The benefits of viewing an object in three dimensions cannot be overstated. The potential strengths and weaknesses of the product are apparent. It also becomes far less likely that your vision will be misconstrued when there is a shared, mutual experience. The ROI on that is practically priceless.

Without a prototype design, it is also much harder to sell potential clients on a product. A prototype, whether virtual or physical, allows your customers to get a real sense of the thing itself. They can even test the viability with their own team’s designers and engineers with access to the prototype design. Blueprints can possibly be misinterpreted by manufacturers. They may not even believe the product will be workable as indicated. This is far less likely with a three-dimensional model and prototype.

Just as your clients and customers will buy into the product with access to a prototype, they can also keep you level-headed. Designers and engineers often have big dreams and intentions. Prototypes help to ensure that they aren’t building a castle in the sky. Beyond this, prototypes enable primary concerns to become evident quickly and easily.

This doesn’t mean that the prototype has to be an intricate, working model, though. Even a simplistic version can work wonders in stimulating the minds at work on it. This occurs through all the various phases of development. Every choice about the prototype is the same as the design and engineering of the product itself. It will be contingent upon your company’s requirements and those of the product.

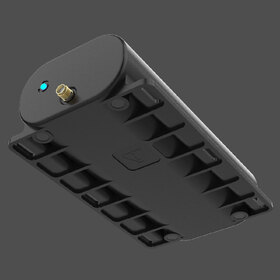

There is little more that needs to be said about why a company needs a prototype design. We have seen the many advantages of this type of design engineering. It is an effective and rewarding process. But who can benefit from it? For starters, almost all industries have the potential to profit from having a prototype design at their disposal.

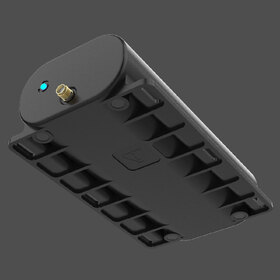

Prototypes, virtual or tangible, work very well for outfits of an industrial nature. Companies in the business of producing anything from manufacturing equipment to goods are prime candidates. If you want to save more in the development process and sell more in the pitching and sales process, you need a prototype of your products.

At the end of the day, a prototype is necessary for any product a company wants to save more money making and make more money selling. This principle applies to essentially every field. Objects as small as pens and as large as cars need prototypes. Wrenches. Firearms. Selfie sticks. Mobile phones. If you can see it, hold it, use it to do something, it probably needs to be prototyped.

Inviting Cad Crowd to be a part of your team gives you the ability to see to the needs of your business as usual, without all the extra headaches of overseeing yet another project. Besides, you get the extra peace of mind that only comes from having the absolutely highest quality prototype design engineers in the world designing your company’s product prototype for virtual or physical manifestation.

We ensure that only the best freelance prototype design engineers around get the chance to work on your project. Our tight-knit group of freelancers are experienced and highly qualified. They have worked hand-in-hand with leaders in every field. Whatever your product prototyping needs may be, rest assured that Cad Crowd engineers will design exactly what you have in mind. We can come up with a prototype solution for every client to meet their specifications.

Cad Crowd will help you by calling on our vast array of vetted engineers. Our network consists of only the best designers in the world. They use the latest technology, so everything will always be modern and up-to-date. If there is a particular software you need us to use, just let us know, and we’ll locate you the perfect prototype design engineer for your project.

Our prototype design engineers are always available to assist any company with either getting started from scratch or building upon a previous design. Wherever you happen to be in the prototyping process, we will help you get to exactly where you need to be to wow your clients and save money in the process.

No other site works with the quality of designers and engineers that we do at Cad Crowd. There is no other place where you will find the level of quality and craftsmanship and efficiency on which we pride ourselves with each contract. Find out how it works or get a free quote if you're ready!

We are different than other 3D modeling and drafting companies in that we offer a complete range of design services. We have a network of pre-vetted, highly qualified professionals ready and willing to help you with your project at this very moment. Whether you need a prototype designed or a CAD model made, we're ready to help. Contact us today for a free quote.