Just about everyone uses some form of fabricated metal part or tool most days of their lives, even without realizing it. Practically everything made of metal formed into a specific shape for use has been through the metal fabrication process. That said, hardly anybody truly knows exactly how that formation takes place or the many different steps needed to make it happen, both before and during the fabrication procedures themselves.

In short, metal fabrication is just a single part of a multi-step manufacturing process that goes about forming unshaped metal (usually beginning in a sheet form of some kind) into either a part or an end product for large-scale use, mass distribution, and/or consumer sales. Pretty much anything that is made of metal and formed into a particular shape is a result of this process. Items like kitchenware, metal piping, (literal) nuts and bolts, and even cars or car parts are all pieces that must go through fabrication.

Far from being limited to such activities as welding, soldering and the like, metal fabricators make use of several different tools and processes, such as metal sheet cutting, metal folding, or the stamping of metal sheets. One thing that many fabricated products have in common is their ability to withstand minor errors in mass production yet still function as intended and designed.

This error tolerance allows for the various techniques and operations to be automated and still churn out an enormous quantity of consumer products that all work as required, even with small differences between the individual pieces. Not all metal fabrication is mass-produced, however. Many metal fabricators are also able to make custom products from specific design schemes. These include objects like modified valves, particular automotive pieces, and other customized hardware units that require more specificity than screws or nails.

Typically, the specific industries in need of metal design and fabrication fall into three broad camps: structural, commercial, or industrial. Some overlap naturally exists across these three general fields of work. The primary difference regards the intended outcome of the fabrication for each sector. In general, structural fabrication sees construction work; commercial fabrication is made use of for consumer goods, and industrial fabrication concerns equipment or machinery.

More specifically, when it comes to structural fabrication work, this includes any metalworking completed during the construction of a building of some kind, from smaller office buildings to skyscrapers. If metal is involved as part of the structure, structural fabrication is too. In these cases, the metal shaping must often be performed by a larger fabrication plant with the ability to complete significant work for use in tall buildings or even for manufacturers to use themselves in their construction projects.

Metal fabrication that is completed for commercial use is perhaps the largest sector for this type of design work and likely the one most people think of when considering such lines of work. Anything that falls into consumer sales fits this particular area of fabrication. Home and kitchen appliances, cars and their parts, and other related products fall into this category. Whether mass-produced or customized, commercial metal fabrication makes many of the parts and products people use each and every day.

Lastly, there is the area of industrial fabrication work. This process has machinery and other manufacturing pieces as its end result. Unlike commercial metal work that has the sole objective of creating consumer goods, industrial fabrication creates equipment that other companies will then use to create their own consumable wares. Hammers, screwdrivers, saws, table saws, and other cutting machines all fit this description. To put it simply, industrial fabrication makes it possible for other people to perform their own fabrication.

In short, then, the industries that require the use of metal fabrication work largely fit into these categories: structural, commercial, or industrial. Whether it’s agricultural machinery, energy sources, consumer goods, automotive parts, construction supplies, or even the military, each of them makes use of similar processes and equipment. The differences lie in the end result of those procedures, which have various aims and uses, depending on the sector and organization in question.

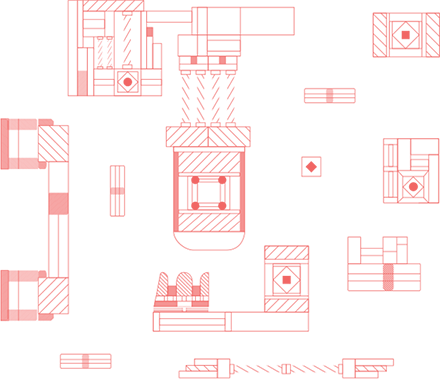

Arguably the most important aspect of metal fabrication hasn’t yet been discussed in detail: metal fabrication design. Before any of the above methods or processes for fabricating metal can be implemented, a metal designer must create a schematic that details exactly where and how to cut or shape the sheet metal in question.

There are two primary ways that companies typically begin with their metal fabrication design projects: with or without a prototype design service. If a business already has a working prototype in hand, a skilled metal designer can help them to clarify the design, refine the schematics, and even run a series of virtual tests on the prototype before committing it to a final digital form. This testing is absolutely key to successful metal fabrication. Without it, businesses are essentially entering blindly into production.

As with most design fields, metal fabrication design is completed almost entirely using computer-aided design (CAD) or computer-aided manufacturing (CAM) software, such as those programs made by AutoCAD, which has been the leader in the field for many years now. This software makes the CAD drafting process far more accurate and efficient than completing the same work by hand (as in the olden days), and, as mentioned, allows for complete testing before production. High-quality metal designers can deftly develop two-dimensional drafts or three-dimensional rendered working models of a prototype for testing and analysis before fabrication even starts.

As suggested above, the pre-fabrication testing process can save both time and money in the long run for all involved. Modern CAD and CAM application packages can run extensive real-world testing procedures on prototypes. These tests make sure that all designs can withstand the actual use to which they will be put in their finished and working environments. As a result, a company can be relatively certain that the formed metal product will execute its function as needed before the manufacturing process gets underway.

Ultimately, the metal fabrication design process determines every aspect of the finished product. What begins as sheet metal ends up as a screw, a car part, or a metal pipe, only after extensive design work has been completed and testing procedures performed. From the particular shape of the parts to the size of each module, and even the actual kinds of metal that need to be utilized, all of this and more is decided upon during the design stage, and not, importantly, on the cutting room floor. In other words, metal design enables peace of mind for every step of the fabrication process.

Allowing Cad Crowd to be an integral part of your team gives you the ability to manage the needs of your business as you ordinarily would, without any extra headaches. What’s more, you get the additional peace of mind that can only come from having the very highest quality metal fabrication designers around the world bringing your team’s vision to life for architecture, design, engineering, or other needs.

Further, we make sure that only the absolute best metal fabrication designers have the chance to work on your project. Our tight-knit group of architectural freelancers have years of experience and are highly qualified in their area. They have worked hand-in-hand with companies and leaders in every field. Whatever your metal fabrication design needs may be, rest assured that Cad Crowd’s freelancers will create exactly what you need for a successful project. We can come up with a metal fabrication design solution for every client, no matter how big or small their project may be.

Cad Crowd will help you by utilizing our vast network of established metal fabrication designers. We only work with the best of the best. Each metal fabrication designer uses the very latest technology, so everything will always be up to date and abide by industry standards. If there’s a particular software that you need us to use for your work, just let us know which one it is, and we’ll locate you the perfect metal fabrication designer for your project.

Our designers are always available to assist any organization with getting started from scratch or building upon previous work. Wherever you are in the process of planning, prototyping, or manufacturing, we can help you get to exactly where you need to be to work intelligently and productively, while saving money along the way.

No other site around works with the same quality of metal fabrication designers that we do here at Cad Crowd. There is absolutely no other place where you will find the same level of excellence, expertise, and efficiency on which we pride ourselves on every contract. Get in touch with us to get started today.