To stay competitive in the global marketplace, companies are increasingly turning to automation. Recent advances in computer hardware and software are making robotics systems more affordable and user-friendly.

To help your enterprise remain at the forefront of cutting-edge technology, Cad Crowd has experts with the experience and up-to-date knowledge for performing robotics design services for residential, commercial, and industrial projects of all sizes.

The use of automation engineering is expanding to nearly all sectors of the economy. Many people see this as a threat to future employment opportunities as workers are replaced by robots, even in fields that were seen as secure from any threat of automation. But the jury is still out on whether robotics will actually create or eliminate jobs.

What is not in doubt, however, is that in many locations across the globe, there is a shortage of workers who are sufficiently trained (or willing) to perform complex, repetitive tasks. Barring a change to this situation, it’s likely that there will be a continuing or expanding need for customized robots and robotic design services.

Even given the availability of a conscientious and reliable labor force, some tasks are really just too demanding or dangerous for humans and are best left to robots. And of course, the top concern for companies worldwide is the increasing cost of labor. We’ll discuss that in a moment; in the meantime, here is a list of ten areas where robots are either currently in use or expected to soon make their presence felt around the world. If you are involved in any of these disciplines, you may want to investigate the use of robotics to enhance your operations:

The growing of crops and livestock is a prime example of an area where the shortage of labor is increasingly being felt. The continuing migration of people from rural to urban areas across the globe means fewer are available to grow our food. But even in areas where there is a potential abundance of labor, increasingly restrictive immigration and migrant work policies are making it more difficult for growers to find workers to harvest crops. This makes farming an excellent candidate for robotics design services.

In addition to helping to alleviate the labor shortage, technology is being used to make farming more efficient. Global Positioning System (GPS) equipment is now routinely used to not only guide tractors while plowing, but to also more accurately plant seed, apply fertilizer, and spray pesticides. So-called precision farming is enabling farmers to control costs by allocating resources at the correct time and only in those areas where they are needed.

Robotics has the potential to play an even greater role in making agricultural operations more efficient. While machinery has been used for years to aid farm workers with the harvesting of crops and with the sorting and packaging of fruits and vegetables, plans are in the works for the development and deployment of autonomous (self-directed) robots that can navigate fields and orchards and perform harvesting functions without human intervention.

It seems that there are as many definitions of the term commercial robot as there are types of actual robots. For our purposes, let’s consider commercial robots as those that are used mainly in business, warehouse, retail, and residential settings.

In business settings, companies are increasingly making use of Robotic Process Automation (RPA), particularly in the financial industry (one of the fields mentioned earlier in this article that had, until recently, been considered to be “robot immune.”) Instead of mechanical devices, RPA makes use of so-called software robots that are now being used to automate all sorts of business processes from data validation to job candidate recruiting and hiring.

Robots are also being used extensively in warehouse settings. Customized robots have been designed that automatically pack products in cases, load cases onto pallets, and then stretch-wrap the pallets for shipping. Automated conveyor systems and even autonomous robots are also currently being used to transport products within warehouses.

In retail settings, robots are now being used to handle a host of functions, including security and customer engagement. The presence of robotics is especially noticeable in the food-service industry, where state-of-the-art technology has moved well beyond mere vending machines. Restaurants around the world are using robots not only to prepare and serve food in-house but to deliver carry-out orders to customers at home.

Another large market for robotics is the residential setting, where robots have been used for years to vacuum floors and clean swimming pools. Robots can be designed to handle other household chores, including gutter cleaning and lawn mowing. Many people are familiar with the Internet of Things (IoT), a system of Internet-connected devices and applications in use around the home. In the coming years, the convergence of IoT and robotics technologies will spawn a host of products and services not even imagined today.

The construction industry has lagged behind other fields in implementing robots, but that is about to change. In addition to a shortage of skilled workers, there are also a number of jobs in this industry that are dangerous, strenuous, or just plain boring for humans to perform. Fortunately, all of these problems can be alleviated to some extent by robotics.

In fact, robotic technology in the form of worker exoskeletons and autonomous vehicles are already currently in use on some job sites. Drones (unmanned, remotely controlled flying vehicles) are being used to photograph construction sites and inspect finished work. Automated brick-laying robots are also now being used.

If you are an owner or manager in the field of construction, you owe it to yourself to investigate how automation can make your business more efficient. Contact us so that we can put you in touch with a robotics design service firm to discuss your needs.

As mentioned earlier, Robotic Process Automation (RPA) is seeing increased usage in business and this applies to the healthcare industry in particular. RPA and its associated software robots have been used for a number of years by insurance companies to automate medical claims processing activities. But hardware robots have also found their place in healthcare and continue to make new inroads.

Robots are increasingly being used by hospitals to deliver medicine and meals to patients and to perform cleaning and sanitation functions as well. Doctors are also relying on medical robots to help them perform dozens of different minimally invasive surgical procedures. These robotic devices make surgery safer by enabling surgeons to manipulate instruments much more precisely.

Telepresence is an example of another exciting area in the medical industry. Telepresence refers to the use of hardware and software to allow people to interact more realistically when not in the same room. The technology goes back several decades with roots in the video conferencing systems available at the time. Today, however, technological advances have expanded to the point where telepresence is being used to train doctors remotely. And it’s also being used by physicians to diagnose and treat patients in cases where the two can’t meet face to face (such as when patients live in remote areas without easy access to medical care providers).

Robots have been utilized in industrial settings for decades, with their use in the automotive industry being perhaps the most familiar application to most people. Robots are of enormous benefit here, performing repetitive or dangerous tasks that would be stressful for humans.

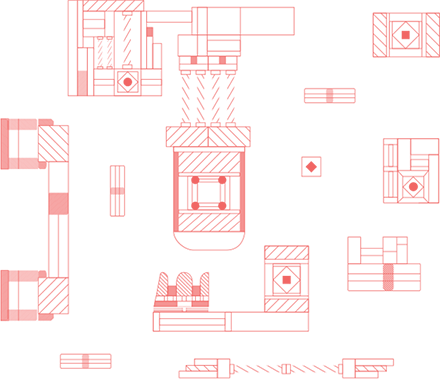

Customized industrial robots have been designed that can perform surface preparation, material removal (like deburring and routing), welding, painting, assembly, packing, palletizing, and many other functions. While these robots are quite complex, they are essentially just machines that are pre-programmed to perform (often only one) function. Because they mindlessly perform their tasks, they are often located away from human workers for the sake of safety. That is beginning to change with the use of autonomous industrial robots, although their adoption is still in its infancy. Because of advances in machine learning and artificial intelligence, industrial robots will increasingly be working side by side with human workers.

The use of robots by the military and law enforcement creates a lot of controversies, not because of the potential loss of jobs they pose in these areas, but because of the privacy and safety concerns of civilians. We can let that debate rest for now – while the concerns are valid, they are and will continue to be addressed by policymakers. In the meantime, it’s important to point out that these two areas are the perfect example of how robots can be used for tasks that are dangerous to humans.

Two of the applications familiar to most people are remotely controlled aerial drones and robotic bomb disposal units. Drones have been in use for surveillance around the world for years now by law enforcement and are also being used by military forces for their remote attack capabilities. And robots that defuse explosive devices have been joined in the field by other units that are used for surveillance, the detection of chemical and radiological substances, and even to pinpoint the location of gunfire.

We may be many years away from armed robots replacing soldiers on the battlefield. But there are many types of military robotic devices currently in use that are saving lives around the globe.

Mining is perpetually listed as one of the top-ten deadliest occupations year after year. Here, too, robots are being increasingly used for tasks that often put human life in jeopardy. Examples of robots that are keeping miners out of danger are remote-control extraction equipment (where the operator is within line of sight of the device) and teleoperated equipment (where the operator works at a remote location). Aerial drones are also in use at mining sites to improve security and help ensure worker safety (for example, drones can be used to inspect a worksite to make sure all personnel has been evacuated before the blasting begins).

In addition to robots controlled by humans, mining operations are making increased use of autonomous robots, mostly in the form of self-driving vehicles including trucks and locomotives to move ores and other material. In addition, artificial intelligence is now being used to help locate underground resources based on data collected at the surface, and AI is even being used to separate ores from waste rock.

Whatever your field of endeavor, robots are likely going to play an increased role in the future. As global competition heats up, companies that take advantage of robot technology and robotic design services will definitely have an advantage over competitors.

As mentioned earlier, the use of automation is a solution to the lack of skilled or even available workers in the workplace. There are other benefits as well. By utilizing a robotics services designer to build custom robotics, you can:

There are other benefits to utilizing robotic automation as well. In addition to the four mentioned here, the bottom line is that robots can improve your bottom line. Companies that incorporate robotic automation stand to see a reduction in production costs, which will result in profit.

Let Cad Crowd assist you in your search for automation solutions. We can put you in touch with the right robotics design company or freelance specialist to help you compete in the global marketplace. Our network of experts possess years of hands-on industry experience, ensuring that you will obtain high-quality results.

Whatever the size of your business, Cad Crowd has the professional resources to help you meet your goals. Our robotics design engineers can formulate a plan to help you increase productivity, maximize the use of your existing floor space, and rein-in labor costs at your facility. We will even back up the quality of their work with our accuracy guarantee.

Our freelance robotics design experts are among the most talented in the industry. We have an extensive network of pre-qualified and vetted professionals available who can help develop and implement innovative manufacturing solutions for your firm. We can help you stay ahead of your competition by crafting a robotic automation solution that will help you control costs and ensure quality – obtain a free, no-obligation quote today!