Your phone, computer, and television can't operate in the same way it’s needed if not within a case. It’s easy to forget that the plastic, metal, or even screens on these devices are just as important as the wiring and power systems inside. These casings make an electronic device functional and it can also attract individuals to the device itself. Whether it be a steel, plastic, or copper enclosure or box, they must lead to a safe and operational electronic device.

Again, you can't use a clump of wires or a group of sensors by themselves. These are many of the essential components of many of the electric instruments that we use. However, to make them operate the way you need them, you need enclosures to give the instrument functionality.

All of these materials used to enclose an electronic device will start as a design. This step is where a team like Cad Crowd can help you find a designer who can create precise and exceptional designs for custom electronic enclosures. The design and development of these casings are almost just as crucial as the internal parts like sensors or wires.

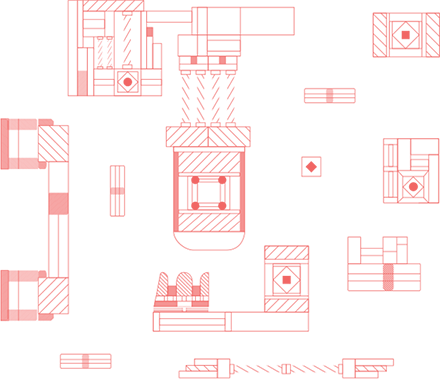

You need a designer that can produce accurate CAD drawings that lead to well-crafted designs. From the measurements to the renderings themselves, hiring a capable and talented designer is an essential first step to creating custom electronic enclosures that meet your design goals.

Whether you’re a solopreneur, entrepreneur, or a CEO of a large corporation, our team is here to make the process of hiring a custom electronic enclosure designer straightforward. Our in-house crew of engineers and designers will work to make sure we find a design professional who is more than capable of using CAD designs, rendering, and prototyping to create the enclosures and cases you need to sell your electronic products.

What can you expect to receive from our electronic enclosure services? For details of how we can help, as well as the types of enclosures our designers can assist you with, keep reading below.

Electronic enclosures are the external shell that encloses electronic devices. This is the surface of the electronic device that we see. For example, the plastic or metal backing of your smartphone, along with the screen, is considered to be an electronic enclosure. Typically, these surfaces are created to be user-friendly, functional, and attractive enough to engage consumers into purchasing them.

Their design and development include sizing, color, and material. They have one of the most critical functions regarding electronic devices as they have to be unique enough to attract potential customers, but also durable enough to protect the internal parts inside of it.

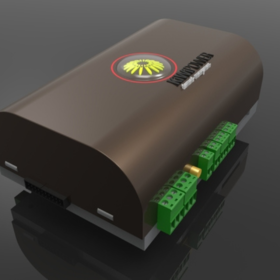

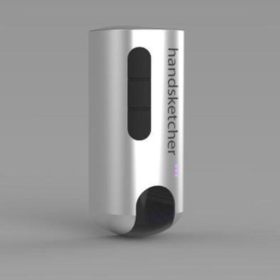

When it comes to custom electronic enclosures, the goal of a designer is to make sure it accomplishes all it is meant to. An example of this would be the plastic encasing of a computer processor device. Designers would have to produce renderings and CAD drawings that adhere to its purpose.

It would need to be designed to house specific sensors, allow for the interaction of an on/off button, and make it possible for consumers to change out items like hard drives. All of these decisions would go into the 3D modeling of customer electronic enclosures.

There are a variety of electronic enclosures, boxes, cases, and housing to choose from. Each one has its purpose and offers a degree of protection from the elements. The National Electrical Manufacturers Association has outlined the various types of electronic enclosures, and codes for them.

Here is a list of the types of enclosures, boxes, cases, and housing. Understanding the types of custom electronic enclosures out there can help you select the best designer to handle the design and development of your enclosure project.

NEMA 1 and 2 Enclosures—These boxes are typically used for electronic products that are stored indoors. Because they are located inside homes and buildings, they offer the least protection from the elements. They protect against light, dirt, dust, and hazardous electronic materials. Even though these enclosures don't provide significant protection from various dangerous substances, they are widely used.

NEMA 3 Enclosures—These boxes and cases are the next step up for custom electronic enclosures. They are typically used outdoors and protect against light, dirt, rain, sleet, and snow. They are not the best option for severe weather conditions, but they can protect against the wear and tear of general weather.

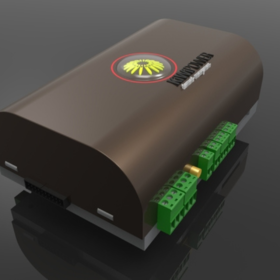

NEMA 4 Enclosures—These enclosures are used to house wiring and sensitive power system materials for industrial and telecommunication systems. They are used to protect against harsh weather conditions and are watertight. The next level up, the NEMA 4x, is meant to protect against corrosion and considerable moisture.

NEMA 6 Enclosures—For protection against temporary water submersion, NEMA 6 enclosures are used. In addition to liquid water, these boxes also prevent ice formation, moisture, and dirt. Much like the NEMA 4, NEMA 6 also has an additional level of custom electronic enclosure protection. The NEMA 6P protects against extreme weather conditions and is used in caves or mines.

Whether you’re building a circuit breaker or a residential power system for housing developments, you have to invest in the right designer to handle this project. Again, this is where our team can assist. From project management to other 3D modeling projects, you have a lot to do.

Helping entrepreneurs manage their design operations has been our goal for the past decade. For a closer look into how we help entrepreneurs and business owners find the best design talent, visit our How It Works page.

The materials used for electronic boxes and cases are crucial to the prototyping and CAD design process. Whether plastic or metal is used, the materials themselves can impact how designers create renderings to move forward in the design process. Here are some of the materials typically used during the design and manufacturing process regarding custom electronic enclosures:

Plastic is a great material for a custom electronic enclosure. It is also more affordable than metal-based options. Nevertheless, other material options out there may work better for your electric device's box or casing.

These are just a few of the material choices for custom electronic enclosure manufacturing. Helping you to select the best materials for your boxes and cases is a vital part of the design and development process. CAD drawings, CAD designs, and prototype designs are impacted by choosing acrylic over aluminum—and vice versa.

Regardless of the decision you make or are leaning to, our designers can help walk you through the process. In addition to the custom electronic enclosure design, our team can offer additional manufacturing-related design services. For a look at the services we provide, take a look at our Manufacturing Services page.

Material selection is only a small part of the customer electronic enclosure design and manufacturing process. Here are a few additional elements involved with the custom electronic enclosure design and manufacturing process:

Design and development—Again, before any actual manufacturing can happen, it is crucial to start designing and developing the custom electronic enclosure itself. This step is where having a talented designer will come into play. Once you hire a designer who is the right fit, this individual can help you walk through the design of your custom electronic enclosure.

They will most likely want to hear about the purpose of the enclosure, specifications, types of preferred materials, and the overall goals of the box or casing. They will use practices like developing CAD drawings, 3D modeling, and design prototyping to put together a rendering of a box or case. You will need to work with this design professional to determine if their design is ready for the next stage of design, development, and housing engineering.

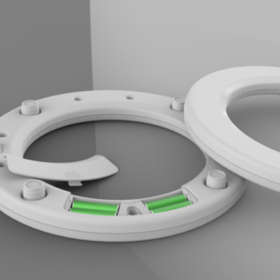

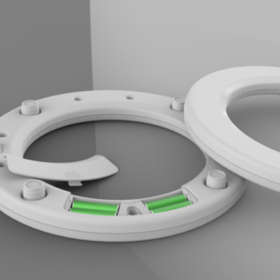

Create a prototype model—Eventually, that rendering and model will be ready for a test run. The goal should be to create a prototype model that allows you to see if the specifications and scope of the initial design work for what you need it to. Does it correctly house the wiring you have? Will it adequately protect the device inside of it? Prototyping allows you to see these elements successfully.

Balancing aesthetics and functionality—Once you have seen that the prototype of a customer electronic enclosure works, it is now time to start the actual process of manufacturing and production. You want to make sure that manufacturers you are working with understand the need to balance how a product looks along with how it functions and is produced. An example of this would be trying to achieve a particular visual style while still paying attention to cutouts and fasteners' placements. Again, look at your prototype and ensure that you are not sacrificing aesthetics for functionality or operations.

Establishing cutouts—As you begin the physical manufacturing process, cutouts are going to be a crucial part of the process. You may want to add these elements for functional reasons: to allow connectors, switches, and wiring. However, you may want to include cutouts that display your logo or add to the device's operation within the enclosure.

Metal fabrication—Depending on the material you chose, tactics like mental bending and fabrication are going to be a part of the manufacturing process. For example, this can look like establishing bend radii for various types of sheet metal used in the production process. Metal fabrication also involves the intersection of two bend lines as well as the placement of cutouts with bends. Metal fabrication can be an expensive and complicated process. This reason is why it is important to be sure you have a designer who can foresee the impact of this technique on designs.

Adding fasteners—The parts of your custom electronic enclosures are going to have to connect in some way. Fasteners are a crucial part of any manufacturing process. Self-clinching fasteners are studs, nuts, and standoffs that are put into sheet metal or plastic to allow for fastening or connection. Each can accept various types of materials to connect the components of an electronic enclosure.

Finishing—Once everything has been fabricated, connected, and signed off on, you now want to put the final touches on your custom electronic enclosure. You want to get rid of any roughness as well as jagged edges. So, one of the last steps in this process would be finishing. This can look like powder coatings, chemical coating, tin plating, or digital printing to label the enclosure or add logos to complete the construction of the device.

There are a lot of moving parts when it comes to manufacturing custom electronic enclosures. It can involve a complex set of steps. However, manufacturing and production processes can be made easier or even more efficient with the right design professional.

A designer can help you prevent costly errors, see where you can decrease or combine parts, and ensure that your enclosure meets all the goals that you have for it. This reason is why our team is dedicated to helping entrepreneurs and business owners like you hire 3D CAD design professionals.

Your finished custom electronic enclosure is as good as the design. So, you want to make sure you are working with the best. Whether you need a NEMA 1 or NEMA 6p enclosure type, our team is here to help add ease to the hiring process.

We understand that a lot goes into hiring the best designer for the job. From conducting interviews to sifting through stacks of resumes, it's challenging to find the time to do everything yourself.

The goal of our team at Cad Crowd is to get rid of the difficulties that come with hiring design talent. Our team of in-house engineers and designers pre-vet each designer before they are added to the Cad Crowd platform.

This means that you are only working with design talent who are experts at what they do. Their portfolios, previous design experiences, and perspectives have been vetted, and our team has determined that they will work well with what you need.

We want to make sure that your company thrives, and that your manufacturing process is time and cost-effective.

In addition to custom electronic enclosure design itself, our network of designers can provide additional enclosure design-related services. Here are some that you can expect:

3D CAD Design—Technical drawings are essential to any custom electronic enclosure design project. Our designers can create exceptional instructions for the manufacturing professionals and engineers that you work with. CAD designs give you detailed and sharp views of an object so they are an excellent tool for designers who are developing electronic enclosures.

3D Modeling—Now it's time to put some detail into that CAD design. Three-dimensional modeling makes it possible to see a realistic view of a product. This is crucial for projects like custom electronic enclosures. You want to get a sense of the scope, texture, and overall aesthetics of a box, case, or housing. This process makes it easy for designers to show you what you can expect once the design is completed.

Prototype Design—Once you have an idea of how you want your enclosure to look, it's then time to see how it feels and functions. Prototype design is where a designer develops the layout of an item with the purpose of it becoming a product that can be physically or digitally produced to be tested. You want to know if your custom electronic enclosure is operational, safe, and ready to be delivered to your customers. Prototype design allows you to accomplish this.

Electrical Engineering—The enclosure has to protect something. In this case, it will likely be the wiring, power systems, and sensors. You need a clear picture of how all these elements work with one another. Our designers can develop technical drawings, model power systems, and ensure that you know how the external enclosure will interact with the components inside of it. Again, you want a custom electronic enclosure that leads to the safety and operation of the device itself. CAD drawings, CAD design, and 3D modeling involving electrical wiring and power systems is a necessary service.

CNC Programming—Computer Numerical Control Programming allows engineers to use computers to control machine tools. This process adds more accuracy and efficiency to the manufacturing process. Our team can help connect you with engineers that offer precise and rapid CNC machining without time lag.

Design for Manufacturing and Assembly (DFMA)—DFMA is a significant part of the custom electronic enclosures process. It requires a keen eye for designing items to be expertly produced and manufactured. Our designers understand the ins and outs of manufacturing and that a design has to allow for a smooth and cost-effective manufacturing process. They can develop enclosure designs that allow for various types of tooling and manufacturing systems. You want to ensure your enclosure is involved in a design and development process that acknowledges the intricacies related to production. Our team can ensure they are designing with manufacturing in mind.

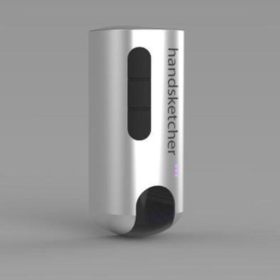

Concept Design—It can be challenging to get from idea to finished product. You may have an idea of what you want your next custom electronic enclosure to look like. Nevertheless, you may need some help in reaching the final form. Our team can step in to help you move through developing a well-crafted design for your enclosure. You don't have to move through the design process alone, and our expert designers can guide you through the entire concept design process.

Metal Design and Fabrication—Every piece of metal used today has been bent or shaped in some way. This process is a crucial part of the custom electronic enclosure process. All metal bends differently and their properties have to be considered during the task of designing. Our experienced and capable designers can take your enclosure concept and design a box or case that takes the procedure of metal design and fabrication into account. From thickness to bendability, our team of designers will ensure your CAD design is ready to move into this step of the design process.

3D Printing Services—3D printing has become a new go-to for companies who want a more efficient and cost-effective manufacturing process. It uses ink and layering to create items as large as homes and as small as batteries. Three-dimensional printing can be a viable option for individuals who want an alternative to metal fabrication and injection molding. Our team can connect you with designers who will develop a rendering for 3D printing services. We can also connect you with 3D printing companies who can handle the prototyping and manufacturing process for you.

3D Product Demo Services—What does your enclosure have to offer to your stakeholders? How is it making their lives easier? How well does it perform? You could tell them, but it’s better to show them. Our 3D product demo services ensure you work with a designer who can animate your custom electronic enclosure to reveal what it can do for your customer base.

From showing top-down views to revealing how it will hold up to weather, 3D product demo services can answer your stakeholder's most pressing questions about your product. Our team can make your electronic device concept come to life, whether it is a circuit breaker or an outdoor power system.

Finite Element Analysis Services (FEA)—Can your box or case hold to the pressures of rain, snow, or extreme heat? FEA is the procedure of testing a design to see if it can handle the stress of temperature, pressure, or other forces. FEA ensures you are giving your customers products that are high-quality as well as safe to use.

The team at Cad Crowd understands that many steps go into the custom electronic enclosure design and development process. We want to take the anxiety and stress out of the hiring and design process entirely. In addition to the services above, we provide a variety of different types of design assistance related to custom electronic enclosures. So, again, be sure to take a look at our Services page for more information on how our team can help.

There are a few ways that we help connect CAD designers with entrepreneurs and business owners. However, one of our most successful and creative is our CAD design and 3D modeling contests. You can receive multiple design ideas and concepts by launching a contest. This prevents you from having to reach out to designers directly or receive a confidential quote if you want to use a different approach.

This method of connecting with a designer is ideal if you have a small project or would like to have a lot of options to choose from. Depending on your needs, this process can add even more efficiency in finding the best designer for your project.

First, you would tell us what you are looking for, which would include the industry, timeline, budget, and the type of design help you need. Next, you can review all design submissions and give feedback to those you prefer until you get the design that fits your needs. Lastly, you would then select the winner and receive your final design. Design contests are an excellent way to receive a lot of design help and concepts from expert designers around the world.

Many of our clients (and our team) have received exceptional designs through this process:

Each contest profile allows you to describe the project, discuss your wants, list what you don't want, and include any additional information to help guide designers to provide the design you need. Again, if you have a smaller project or need help expanding on your design concept and idea, design contests are a great way to get to a solution that fits.

If you are interested in setting this up or need help in navigating this process, we encourage you to reach out to the Cad Crowd team. Many of the clients that participate end up receiving over 100 submissions, so there will be many options for you to choose from so you can find the design that best fits with your company's needs.

Again, you have a lot to handle. From accounting to managing vendors, you don't have the luxury of time. Our team understands that you need a design process that incorporates efficiency and convenience. This reason is why we have tried to add ease to the design hiring process for the last decade.

Hiring a freelancer is one of the most strategic and effective actions you can take for your company. There are a variety of benefits you and your team can look forward to:

Save on costs—Hiring a freelancer means that you can avoid many of the hiring costs that come from hiring a traditional full-time employee. Also, it is easier to come to a mutually beneficial wage that fits in your hiring budget and is attractive enough for a freelancer to want to work with your team.

Get help from an expert—Today's hiring landscape is competitive. As a result, it can be hard to find exceptional design help on your own. Fortunately, the Cad Crowd team pre-vets all designers who are a part of the network. This process ensures that you are working with a CAD designer who is an expert in their work.

Hire the best, regardless of location—Choosing to hire a freelance professional through the Cad Crowd platform makes it easy to find the custom electronic enclosure design help you need, regardless of where this person is located. The best fit for your project could be someone in Thailand, or it could be a design professional from Texas. Geography is no longer a limitation when it comes to hiring a freelancer.

Free up your team—Even if you have an in-house design team, you likely want them working on projects requiring their strategy and specialized expertise. Hiring a freelancer allows these individuals to work on projects or tasks that they are specially equipped to handle.

Get an outside perspective—Hiring a freelancer can give you new insight into the work you do. So, not only are you able to receive assistance from an expert designer, but you can also take advantage of the fact that they can offer fresh ideas. Since they are not working with your team on a full-time basis, they can bring their own perspective on your work processes from other projects they have worked on.

Hiring a freelancer is a great way to add some new ideas and talent to your team. It is cost-effective, efficient, and can benefit your company in the long-run. However, this process starts with working with a team that can help you find the best professional for your custom electronic enclosure project.

Whether you are just starting with a concept drawn on a napkin or have a fully-fleshed out vision of what you’re looking for, our team can offer the assistance you need in your custom electronic enclosure project.

Finding the right fit for your project ensures that your design and development process gets off to the right start. It can reduce mistakes, ensure that you are staying on budget and that your box, case, and housing engineering fit the criteria you are looking for. Therefore, it is crucial to take time to invest in this process.

If you are ready to start the custom electronic enclosure process, we invite you to reach out to us for a free quote today!

At Cad Crowd, we have the privilege of working with hundreds of the best engineering and electric designers in the world. If you're looking for some help designing your electronics enclosure or anything else, don't hesitate to contact us for a free quote.