Have you come up with an excellent product idea? Congratulations! You may have thought about how to market it, the budget for production, and even how to present the idea to your stakeholders. The beginning phase of excitement and creation is an important one. However, before you make any formal arrangements, you have to get into the weeds and the details of production.

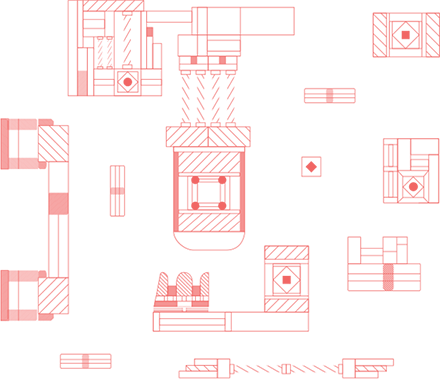

You may have an idea that is right for your audience. Nevertheless, it may not be engineered in a way that is easy for manufacturing and assembly. This is why design for manufacturing and assembly (DFMA) is a valuable practice for developing and building products. Some may use the manufacturing and assembly concepts interchangeably, but they are distinct.

Design for manufacturing focuses on the creation of parts, and design for assembly highlights the assembling of the components during production. Putting these topics together allows you to address both pivotal elements of the production cycle.

The last thing you want for your product is for it to make it to the production floor and for those helping to put it together to have difficulty producing it. You face an uphill battle if your product is not built for machines. The way to avoid this problem is to make DFMA a priority. DFMA allows you to reduce costs and optimize the time spent taking your product from ideation to completion. If this sounds overwhelming, you have come to the right place.

You do not have to handle the process of DFMA on your own. For almost a decade, the team at Cad Crowd has helped entrepreneurs like yourself find experienced designers who can help them add DFMA to the production process. If you require a product design service and want to know why DFMA should be a priority, we invite you to keep reading below.

Years ago, the production floor and your company would have likely been in the same place. You would have been able to see what was happening and step in to help resolve any issues regarding your product. Today, things are different. More companies are outsourcing their manufacturing and assembly processes.

Also, many innovative companies have emerged to handle production efficiently and at a reduced cost. As a result, another state, country, or even continent could be the production site. This situation is one of the primary reasons DFMA should be a priority for your company. The logistics, time, and costs involved in getting your product set up for production—likely thousands of miles away—can be wasted if your product is not made for the unique production site.

Another factor that makes DFMA a requirement is customer demand and expectations. Today, customers are expecting higher levels of customization and responsiveness than they ever have before. This scenario means your product must fulfill their needs while arriving promptly. Did you know that 73.6 percent of consumers reported that delivery is most important to the shopping experience?

When you fail to make DFMA a significant component of your production cycle, you are running the risk of experiencing shipping and production delays due to your product not being able to go through assembly efficiently. A part could have gotten caught in a machine due to an incorrect measurement. Also, there may be too many variations of the product for the factory to handle. DFMA allows you to plan not only for the product itself but also for the factory at the production site.

Lastly, DFMA is essential to having a reliable and well-created supply chain. Creating products with DFMA in mind allows you to streamline steps involved in your supply chain process. According to the Logistics Bureau, businesses with optimal supply chains have 15 percent lower costs than those not focused on optimization.

DFMA is a form of optimization, and the very nature of what it is makes your production and corresponding supply chain effective. When you reduce costs during the supply chain, you increase your margins. DFMA can help decrease the resources needed, and enable you to minimize the hiccups that could occur and negatively impact your production and supply chains.

There are many benefits associated with making DFMA a part of your production strategy. Nevertheless, the first step in beginning the process is hiring a designer experienced in engineering, manufacturing, and design.

It may seem daunting to have to add another thing to your plate. However, recruiting a capable designer can ensure that this process is one you do not have to add to your list of to-dos. At Cad Crowd, we have three main ways that we use to help match CAD designers with entrepreneurs. For a more in-depth look into how we do this, and how it can benefit your company, take a look at our How it Works page.

DFMA can lower your expenses while still enabling you to create high-quality products that meet the demands of your customers. Again, you may have an excellent idea for a product. However, a product is only as good as its engineering. For your product to have the functionality you envision, you need to start with a design that makes the manufacturing and assembly process straightforward.

So, here are some ways DFMA can benefit your bottom line and help you decrease costs so you can increase margins:

These are a few ways DFMA can lower production costs and free up time. These topics may seem to amount to many steps, but an experienced mechanical engineering service will do what they can to ensure you save as much money and resources as possible with your design. So, whether you are establishing a concept or feel ready to go to production, it is always a great idea to allow a designer to simplify your design.

We can get you started with the first step. Our team has helped countless other entrepreneurs find talented and experienced designers who have helped them optimize their production cycles. Preparing for DFMA doesn't have to be a complicated process. You can begin working with a designer who makes the reduction of your manufacturing and assembly costs through design, their priority.

To genuinely understand the value of DFMA, it helps to look at the significance of both DFA and DFM separately. Understanding the value that each practice brings to the overall concept is essential to seeing DFMA as a priority.

Design for Assembly: This practice is solely concerned with reducing the cost of product assembly. It is used to help design teams develop products that can go through production at a lower cost. The ultimate goal is to make the assembly process less sophisticated. So, for the DFA part of DFMA, the objective is to minimize assembly operations and focus on creating ease with the number and types of components used.

In practice, this looks like this:

Design for Manufacturing: Here, the goal of a designer is to take down the cost of producing the actual parts used in the manufacturing process. Much like assembly, the objective is also to reduce the number of manufacturing operations and use standard components that are easy and cost-effective to produce.

What this looks like in practice:

Both concepts are integral to production efficiency and cost savings. Together, they should enable you to lower the product development cycle time and reduce your overall production costs. When you work with a designer, the sequence of how both will play out is as follows:

Develop the concept ->Design for assembly ->Selection of materials->Design for manufacturing->Flesh out the final design

Your concept will lead to the management of how parts will be put together. From there, you have an idea of the components that must be developed to help move the product through the assembly process. It makes sense, as before the physical work on the parts begins, you have to understand the factory where the assembly takes place. These two ideas make DFMA a complete and single methodology that allows you to plan for the entirety of the production process.

It isn't challenging to see that DFMA requires a keen and talented eye for assembly and manufacturing strategy. In this case, the design is not only used to convey aesthetics. Its primary purpose is to help your bottom line and prevent costly production inefficiencies. Again, 70 to 80 percent of the cost savings happen during the design stage. This scenario makes the process of finding the right designer for the job essential to the success of your DFMA project.

Deciding to outsource your DFMA services is an even better idea for you and our team. Outsourcing brings additional cost-savings, talent, and support to your project.

Here are a few specific benefits of outsourcing your DFMA services:

Keep up with the competition: More than one-third of businesses outsource, and in 2019, it was projected that 52 percent of companies would start. It is likely that if your competitors aren't already doing it, they are thinking about it. Outsourcing gives you a competitive advantage that puts you on the same playing field as your peers.

It reduces your costs: A 2016 Deloitte survey of businesses that outsourced found that 59 percent of these respondents chose to outsource to reduce their costs. Outsourcing your services enables you to only pay for the work done. As a result, you typically don't have to add yearly salaries or other high hiring costs to your budget.

Frees up your team: Again, referencing the survey, the second reason businesses choose to outsource is the ability to focus on core functions (57 percent). A task as big as DFMA needs to have its own set of eyes on it. However, your team also has its own projects to manage. Outsourcing gives you and your team a chance to focus on things that only you can do.

Satisfy your customers: Since you have someone dedicated to ensuring the DFMA process runs smoothly, you can also benefit from the aspects that improve customer service. For example, having an outsourced freelancer handle DFMA makes it much more likely that products will go through the manufacturing process efficiently. This situation allows for reduced shipping time, higher-quality products, and higher response times.

Gain access to exceptional talent: If you hired an outsourced individual full-time, the hiring costs, along with the salary, would likely create a massive drain on your budget. Fortunately, the Cad Crowd platform makes finding excellent talent at an affordable price easy. You only pay for the work you need, whether by the hour or project.

Get an outside opinion: Even the best companies have a culture that may make it challenging for new ideas to flow. Outsourcing is a great way to fix this. You have access to a talented individual who can offer a unique perspective that could be an asset to your company. This person is someone who may have similarly worked with other organizations and can give a nuanced opinion on how they can help.

Bypass a lengthy hiring process: Who has the time to wade through hundreds of resumes and conduct multiple interviews? The hiring process takes a lot of patience, dedication, and time. We want to help lighten the load. The Cad Crowd platform makes it easy to find the freelance talent you need for your next DFMA process. Whether you would like to receive multiple bids for a project or need a confidential quote, our team can help you find the design support you need.

We want each entrepreneur we work with to realize the benefits above. We want to help your bottom line while also reducing the amount of work and costs associated with DFMA. Our team understands that finding the right designer for the job is essential.

We have helped the likes of PepsiCo, Tiffany and Co., Yale University, and countless others find designers for their projects. We believe that design should help to align with and further your business goals, and DFMA is an excellent practice for accomplishing this.

Regardless of where you are in the DFMA or production process, we are ready to help you move to successful production.

Please check out our services page for related or additional DFMA services. We have designers who specialize in manufacturing, architectural, and CAD design. So, see how else we can help support your next design project.

Check out our How it Works page if you haven't already. There, we detailed how we can help you find a designer who fits your DFMA project. If you are ready to begin the process and would like our team to review your project plans, we invite you to contact us for a free quote.

At Cad Crowd, we have the privilege of working with some of the best freelancers in the world. Our team consists of qualified CAD design services, 3D rendering companies, and even product design experts. If you're in need of any assistance, get in touch with us for a free quote today.