This quote couldn’t be more accurate when we are discussing the practice of design for manufacturing (DFM). DFM puts the thought process of designing for production efficiency on display. By definition, DFM is the practice of creating parts or products for ease of manufacturing, with the ultimate goal being to lower the cost of the production process.

Whenever you step into your car, use an eating utensil, or purchase a new piece of furniture, know that these products have likely gone through the DFM process. They are not only engineered to be used for their intended function, but they also were designed in a way that would allow them to run through production efficiently. Designers and engineers are continually fine-tuning the design of products to ensure this happens.

DFM doesn’t just help the company, but the consumer directly benefits from cost-savings and efficiencies. For example, the fewer parts used, the lower the cost and the higher the likelihood of distributing a product at an affordable price with a faster time to delivery for customers.

There are countless benefits to investing in DFM. However, the first step in realizing these advantages is to find an experienced designer. This individual can design your next product for ease of manufacturing. This designer should be experienced, capable, and have an exceptional understanding of production and engineering.

If you feel overwhelmed at the thought of attempting to hire a designer with expertise in DFM, we understand. Knowing where to look along with having to run a time-consuming hiring process can be challenging. This reason is why the Cad Crowd platform exists. For a decade, our team of designers and engineers has helped entrepreneurs and business owners find the design help they need.

We know that you have a lot to manage as an entrepreneur, and we want to make the design process as comfortable and straightforward as possible. For a closer look into how DFM is the right addition to your production cycle, and how our team can help, we invite you to keep reading.

“Design adds value, faster than it adds costs.” – Joel Spolsky, creator of Trello

At its core, the practice of design should add value to your business, and in turn, help you add efficiency and low-cost processes to your production cycle.

Also, it can help to bring about innovative techniques that not only push manufacturing forward but also impact the company as a whole. Here are some of the recent DFM trends which have been taking center stage over the last decade:

From 4D printing to cloud-based computing, today’s advanced technologies are impacting every facet of the manufacturing process. As a result, designers have to stay informed on each of these technologies—and any that are emerging—to correctly design a product for manufacturing. There will always be new technologies to incorporate into a design process. Savvy designers understand this.

However, it also helps you and your firm to be aware of what’s out there. Additive manufacturing may be the best answer to your manufacturing logistics issues. On the other hand, a mobile robot may be the best way to take care of quality control. Whatever the answer is, knowing innovative technology trends is key to staying ahead of the competition.

Our team at Cad Crowd wants you and your company to have a competitive advantage. This reason is why we want to connect you with the most capable designers. So, for a closer look into how we match designers with excellent entrepreneurs like yourself, please look at our How it Works page.

When you sit down to work with a designer about DFM services, some key topics should be addressed during the design process.

What factors lead to a successful DFM process? Take a look at our list:

Complex requirements—You may have an excellent idea for a product. It may serve your client’s needs and can bring in the necessary revenue. Nevertheless, it would help if you allowed a designer to sit with your idea and see if there is a way to simplify the requirements. There could be some unnecessary parts, while some of the sizing specifications may need to be altered to allow for easier assembly. The goal of a designer is to take your product design and break it down to its simplest components. So, always look at your concepts and see if there is a way to add simplicity to the idea or the parts needed.

Handling variations—What if you’re building a product that has a variety of different types of parts, shapes, and sizes? In today’s market, where customers prefer customization, it is not realistic to ignore variations altogether. So, you must inform designers of all the potential alternatives of a product. It will be up to them to incorporate this into their design and plan for various necessary parts and components used during the design process.

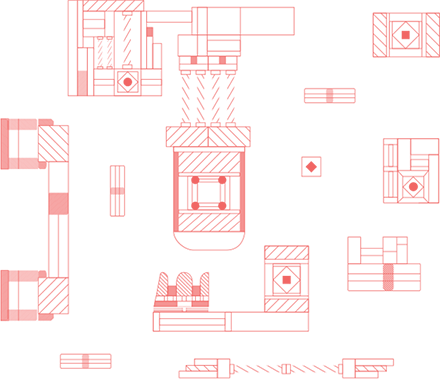

Production strategy—How does your design fit with the manufacturing process? How easy is it for equipment to move through machines? The designer will see how each of your product components can be routed through the tools in the factory. There should be a strategy for how the product is built and how the parts will be spaced to allow for easy assembly. This situation requires that a designer understands how the manufacturing process happens at your company so they can adequately plan for it.

A modular approach—When you develop a product, you want to look past the current project and keep the future in mind. For example, if you decide to upgrade your product or introduce a new—but also similar—product, you don’t want to have to start from scratch. Your product should be built in a way that allows for modular design. This scenario makes it easy to remove specific parts from the design without starting at the very beginning. This step will not only save you time and money, but it will also make it much easier to institute product changes.

Documentation—How much does each part cost? Was it easy to find and transport to your factory? How long does the entire process take? You need to document every aspect of the production cycle, especially when DFM is involved. Again, you may want to introduce a similar product or start over with another type of offering. Having the right documentation will prevent you from making repeat mistakes and allow you to find the materials and suppliers you need quickly. The more you document, the more you will have the information you need to begin the next process without difficulty.

Planning for errors—How will you analyze mistakes and have a plan for addressing them. DFM should address this, and make the process of quality control streamlined and efficient. Whether you have a robot monitoring for errors or a team doing a detailed analysis of each product and component, the ability to test for mistakes should be straightforward. This step is a crucial part of the design process that should be discussed when you are planning for DFM.

Handling cost—One of the primary goals of any DFM project is to minimize time and expenses. The minimization of parts and ensuring each component of a product lines up with a piece of machinery helps to lower cost. A shortened production cycle means decreased labor time, which should also drive down the expense. Reducing expenses is a significant component and a benefit of the DFM process, and savvy designers will acknowledge this as they help to bring ease to the manufacturing and design process.

Each of these topics should be on the table when you sit down with a designer to determine DFM. As a result, selecting a designer is critical to the next manufacturing process. You want someone who understands the goals you are trying to achieve and can use design to strengthen your production and manufacturing system. This reason is why the Cad Crowd platform provides you with a straightforward process for finding the designer who is best suited for your next DFM project. You deserve to work with the best, and our in-house team of engineers will work with you to help find an exceptional designer for what you need.

There are many steps to the DFM process. There are also a wide variety of related services that you may need along the way. Regardless of what you may need on this list, we have a global roster of skilled designers who can take care of these services and provide the design help you need. Here are some DFM-related and additional services our team can offer to streamline your production and manufacturing processes:

Internet of Things (IoT)—The future is now when it comes to network connectivity. Every device is connected while also collecting data. Our team understands how important this emerging technological advancement has become, especially for businesses. Whether you are designing a machine to be a part of IoT, or need your manufacturing systems to account for this new advancement, our designers are prepared to take the lead.

Product engineering—While designing for efficiency is a hallmark of the DFM process, it is also essential to ensure the design is engineered to function as originally intended. Our designers know that you are continually having to adapt to changing consumer tastes. This situation can make the process of constantly having to engineer new products, daunting, and time-consuming. Well, excellent engineering starts with exceptional design. The team at Cad Crowd will help you find a talented designer who can help you develop a high-functioning product that meets the demand of your consumers.

Tool design—It is nearly impossible to create the right product without the appropriate tools. You need tools that are going to hold up under the stresses of repeated production. Our team of designers can work with your designs to ensure that your manufacturing tools can meet the needs of your production goals. Regardless of whether you need special tooling or need to ensure a large-run happens without fail, our designers can exceptionally develop your next tool designs.

Concept design—It takes much work, creativity, and effort to get from an idea to the finished product. DFM is all about taking your concept and making it efficient for manufacturing. However, before we get to the DFM phase, you first have to develop a capable concept. A Cad Crowd designer can help you during every step of the conceptual design process. Whether you have yet to put pencil to paper or already have sketches, our team can work with you to ensure your concept is ready to move onto the next phase.

3D printing services—As stated above, 3D printing is an emerging way for companies to manufacture products accurately. It works very much, in the same way, as a traditional inkjet printer. The only difference is that it is producing objects by depositing layers of materials to create 3D objects. It is fast and, in some ways, more affordable than traditional manufacturing methods. Whatever the object or material, we have a community of 3D printing companies to connect you to for the next step in your manufacturing process.

Metal design and fabrication—Metal is a common material used in prototyping many of our devices and everyday objects. Metal fabrication shapes this metal through folding, cutting, stamping, and other methods. Whether you are automating these processes or have manual manufacturing systems, our designers can work with you to design metal objects that can be efficiently and accurately fabricated for consumer use.

There are many ways Cad Crowd freelance designers can help you walk through the DFM and general manufacturing process. There are various steps depending on the product you are producing, the materials used, and your production goals.

Nevertheless, our capable and talented designers are ready to help you move through the production process. Whether you need help preparing your design for 3D printing or developing new and reliable tools, our team is more than ready to help. For a closer look at the help we can provide, we invite you to look at our Services page. There you can see the additional design help we can offer to you and your team.

When you make DFM a priority, there is a wide range of ways to impact your company for the better. Here are a few ways DFM can give your company a competitive advantage:

Overall, DFM can provide a variety of benefits to you and your company. From improving supplier partnerships to avoiding production delays, it can give your company the competitive advantage it needs. However, again, the first step to realizing these advantages is hiring a capable and talented freelance designer. This individual is someone who understands the relationship between manufacturing, engineering, and design. Fortunately, we have an in-house team of engineers who are ready to help you find the right designer for your next project.

Here is what you can expect when you allow a Cad Crowd designer to help you with your next DFM project:

When it comes to DFM, you want someone on your team that understands the intricacies of design and how this process can lower your costs and benefit your company as a whole.

Again, for a decade, Cad Crowd has helped entrepreneurs find experienced designers who are more than ready to offer their assistance. So, regardless of what your needs are, our team is prepared to help you find the best professional freelance designer for your DFM project.

At Cad Crowd, we work with thousands of the best 3D designers, product designers, and CAD services in the world. Our freelancers have experience fulfilling projects for top-tier companies including Tupperware and PepsiCo. If you'd like our help, get a free quote today.