Global rank:

1,632

/

96,215

Skill pts: 20

About

Starting out in product development, I learned to see things from a product life cycle perspective. I took pride in understanding the DFM, DVT/EVT, GD&T, and DFMEA steps required to bring a product to life. It was also my first opportunity to travel abroad for work as most of our suppliers were overseas. I became interested in domestic manufacturing as a way to be more hands on in the process. I took on a role that allowed me to make a tangible impact, both to the products we made, but also to the people that made them. This was when I realized how much value I put in helping others. After a year volunteering overseas, I got my Master's degree with a focus in electronics and control systems. I was able to leverage this to help develop software using precision motor control for prescribed motion.

Design Entries

Experience

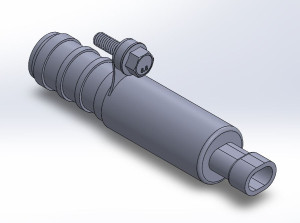

- Mechanical Engineer CEVA, Inc. · Full-time Oct 2021 – Jul 2023 1 yrs 9 mos Rockville, MD, United States Provided vital hardware support for software development, creating innovative fixtures, robust enclosures, and fully customized motion systems. Managed a plethora of mechanical engineering projects, from concept to part design, to technical drawings, sourcing fabricators, and 3D printing. Ensured solutions met functional needs, stayed within budget, and adhered to schedules. Gained experience with packaging, artwork, renderings, modular assemblies, rigorous testing, and precision motion sensors and controllers.

- Mechanical Engineer ARTAZN · Full-time Oct 2016 – Aug 2019 2 yrs 10 mos Greeneville, TN, United States Increased production capacity by 25%, improved quality and safety, and complied with OSHA and EPA. Boosted diameter inspection speed 10 times by integrating line scanner to quality inspection machine. Developed and implemented high speed (15 coins per second) coin turner critical to machine design. Performed CAD modeling and drafting to relay projects between supervisors, vendors, and contractors. Gained experience with welding, plating, annealing, casting, pressing, machining, and optical inspecting.

- Mechanical Engineer American Accessories International, LLC · Full-time Dec 2013 – Sep 2016 2 yrs 9 mos Knoxville, TN, United States Led international manufacturing of high volume (>300,000 pcs) consumer electronics including design for manufacturing, safety testing and certification, production validation, quality inspection, and fulfillment. Investigated with design firm, factory, and client to identify & resolve cause of 5% product defects. Performed CAD modeling, developed prototypes, and identified solutions to supplier and customer needs. Gained experience with plastic injection, high pressure die casting, machining, plating, and SMT assembly.

Education

- University of Virginia Master of Engineering, Mechanical Engineering, 3.91/4.0 2020 – 2021 Activities and Societies: null

- University of Virginia Bachelor of Science, Mechanical Engineering, 3.57/4.0 2011 – 2014

Licenses & Certifications

- Certified SOLIDWORKS Expert - Mechanical Design Aug 2015 – Present See credential